Surface Roughness Contour Graph Profilo meter Testing Machine

1.Product name:Surface Roughness Profiler Integrated Machine

2.Product model:SRT-7150

4.Key advantages

Dedicated to precision measurement for decades!

Through ISO9001 quality management system certification, knowledge

management system certification;

National intellectual property advantage enterprise certification;

Through the export of EU CE certification;

lProduct diversification: Support customer customization;

5. Instrument description and measurement range:

SRT-7150is an integrated measuring machine equipment for surface

roughness and contour measurement.

The surface roughness and profile of various workpieces are

measured and analyzed by using high precision grating measurement

system, high precision grinding guide rail, high performance

non-contact linear motor, high performance roughness measurement

module, high performance computer control system technology and

perfect multi-functional software.

The device can measure various parameters of various mechanical

parts, such as plain line and cross section profile parameters,

surface waviness parameters, roughness parameters and so on.

It can measure the straightness, inclination, angle processing,

circle processing ( distance from straight line to tangent line,

distance from circle center to circle center, radius of arc,

distance from intersection point to circle center, distance from

circle center to straight line ), point line processing ( distance

from intersection point to straight line, distance from

intersection point to circle center, intersection point of two

straight lines, distance from intersection point to intersection

point ), logarithmic curve, groove width, groove depth, groove edge

distance, groove center distance, inclination, horizontal distance,

vertical distance and other shape parameters of various parts.

It is suitable for bearing industry, mechanical processing,

automobile, motorcycle, precision hardware, precision tools, molds,

tools, optical components and other industries.

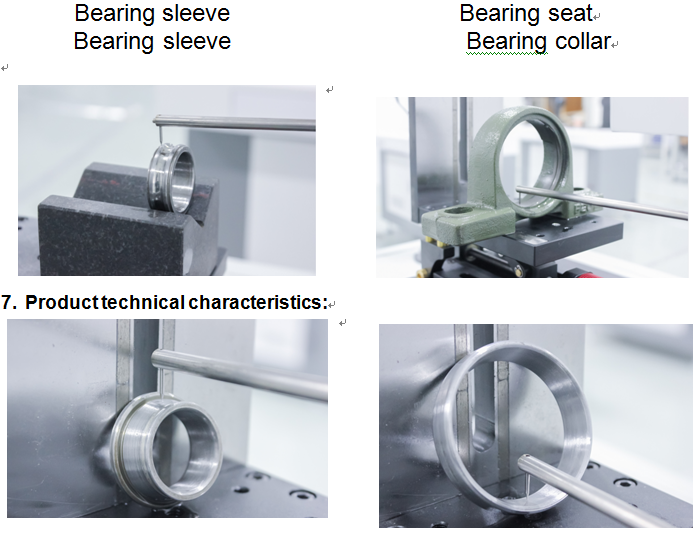

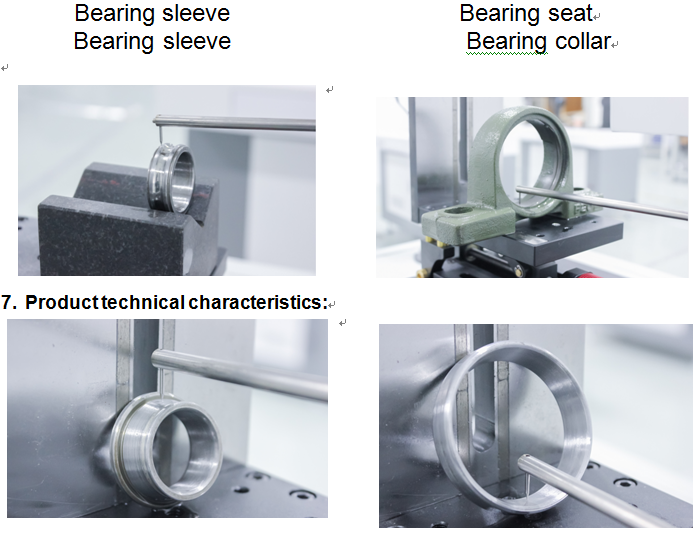

6.Application cases:

pistonPrecision spring

(1) High precision, high stability, high repeatability, long

service life;

1) The leading high-precision grating measurement system and

high-precision inductance measurement system are selected, and the

measurement accuracy is very high.

2) Independent research and development of high precision grinding

guide rail system, guide rail material wear resistance is good,

ensure the system stable and reliable work ;

3) High performance linear motor drive system ensures high

measurement stability and good repeatability.

4) The measuring table can adjust the Y direction, horizontal

direction, horizontal sector direction and various angles, and can

adjust various angles, which is greatly convenient for user

measurement requirements.

(2) Intelligent software system:

The instrument operation interface is friendly, the operator can

easily master the instrument operation, and the use is very simple.

1 ) The practical measurement software design experience

accumulated by the company for many years provides customers with a

simple, practical and fast operation experience ;

2 ) Powerful, automatic processing of data, print reports of

various formats, automatic display, print, save, query measurement

records ; the data can be archived or printed centrally without

occupying the verification operation time.

3 ) The measurement range is wide, which can meet the special

measurement function of almost all types of workpiece contour

measurement, including special workpiece screw, bearing, thread and

so on.

4 ) The measured section can be selected automatically and manually

for evaluation, and the software function can be customized

according to customer requirements ;

5 ) Using computer large capacity database storage, can record all

the verification results.

8. Environmental requirements for use:

1)Power demand : about 500W

2)AC Power: 220V ± 10 %, 50Hz

3)Environmental requirements : temperature - 10 ~ 30 °C ;

4)Relative humidity : < 85 %

5)There is no obvious vibration source at the installation site

6)Individual ground wire

7)There should be no dust, vibration, noise, air flow, corrosive

gas and strong magnetic field around the room that may affect the

measurement. Maximum ground vibration RMS: < 50HZ 2.5μm/s >

50HZ 5.0μm/s

9.Technical parameters:

| Project Model | SRT-7150 |

X axis Sliding linear guide rail | Movement accuracy | ≤0.5μm /80mm |

X -axis positioning Grating ruler | Resolution | 0.1μm

|

| Place of production | China |

| Data sensor | Resolution | 0.02μm |

| Place of production | Imported abroad |

| System resolution | 65536:1 |

| Linear accuracy | ≤±(1.5+|0.2H|)μm |

| circular arc | ≤±(2+R/8)μm |

| angle | ≤±2′ |

| Straightness | ≤0.8μm/100mm |

| Roughness measurement |

| Measurement range | X-axis | Ra:0.01 - 10μm |

| Z1-axis | ±500μm |

| Evaluation parameters | Roughness evaluation

parameters:Ra,Rz,Rq,Rt,Rp,Rv,Rc,Rdc,Rsk,Rku,Rsm,Rmr,Rdq及Rmr(c); Ripple degree evaluation

parameters:Wa,Wz,Wq,Wt,Wp,Wv,Wc,Wdc,Wsk,Wku,Wsm,Wmr及Wmr(c); Original contour evaluation

parameters:Pa,Pz,Pq,Pt,Pp,Pv,Pc,Pdc,Pdq,Psk,Pku,Psm,Pmr及Pmr(c) |

| Sampling length-L | 0.08,0.25,0.8,2.5,8(mm); |

| Evaluation length | According to GB / T10610-2009 standard implementation |

| Indication error | ±5% |

| Repeatability of indication | 2% |

| Profile measurement |

| Measurement range | X-axis | ≤150mm |

| Z-axis | ≤300mm(Can be adjusted according to user needs) |

| Z1 | ≤40mm |

| Moving speed of table | 0.05-0.8mm/s (Four gear, automatic speed regulation) |

| Working environment | Working tempreture:10℃-30℃(normal temperature) Humidity 20-80%RH No obvious vibration source |

| Required power supply | 220V 50Hz 0.5Kw Individual ground wire |

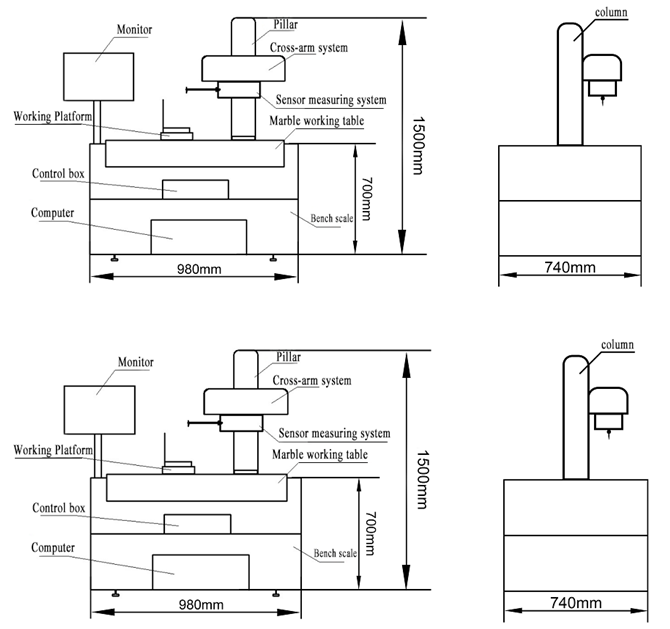

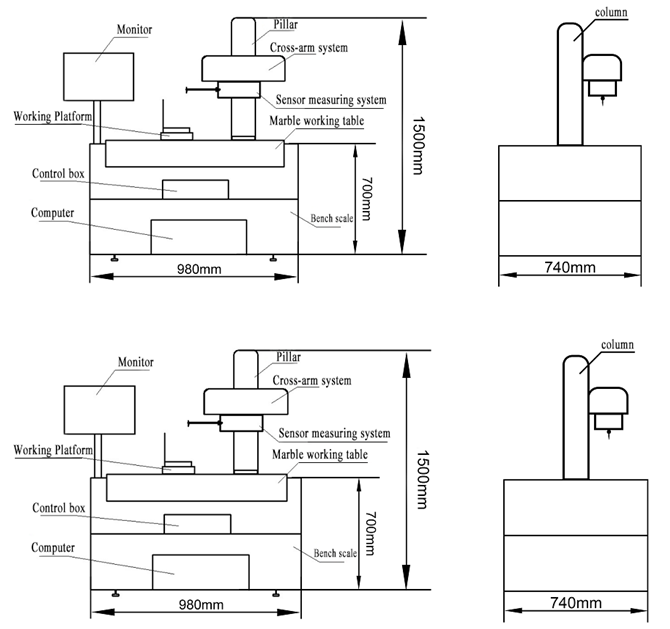

| Instrument size (length × wide × High) | 980×740×1500(mm) |

| Instrument weight | about120Kg |

Note: The above technical parameters can be adjusted according to

the actual needs of users. You are welcome to consult our

technicians on various issues.

10.Equipment size:

11.Product standard configuration:

Part name

| Project name |

| Mechanical part | Host instrument frame x1 |

| Marble working table x1 |

| Universal precision adjustment table x1 |

| Column system x1 |

| Horizontal guide rail moving device x1 |

| Electrical part | electrical control system x1 |

| Linear grating x1 |

| Inductance sensor x1 |

| Computer x1 |

| HPInkjet Printers x1 |

| Special measurement software x1 |

Standard Parts

| Standard size ball x1 |

| High standard block x2 |

| Roughness instrument standard block x1 |

| Needle | Probe and measuring needle (Two axe-shaped, two pointed) x4 |

| Others | Standard toolboxx1 |